UK Distributor of Sponge-Jet: Discover the Power of Abrasive Sponge Technology

A world leading solution for surface preparation, surface cleaning and decontamination.

Matom SpongeTech is redefining the UKs approach to abrasive blasting with Sponge-Jets environmentally responsible Technology. The leader in clean, dry, low dust, re-usable abrasive blasting.

Sign up for a demo and discover world leading technology.

Outdated methods could be costing you in more ways than you thought…

Traditional blasting techniques have been the standard for decades, but that doesn’t mean they still fits today’s world. Dust, waste, disruption and environmental hazards are no longer acceptable. It’s time for a cleaner, smarter approach.

Discover a better way with Matom Sponge-Tech

-

Traditional blasting methods are restrictive and struggle to adapt across different surfaces, contaminates and project requirements. They offer limited control over surface profiles and preparation, resulting in the need for costly, multiple blasting systems.

-

Traditional approaches such as sand and grit blasting produce excessive volumes of hard-to-manage waste, driving up costs and creating logistical challenges for storage, disposal, and transportation.

-

With traditional methods, airborne dust, debris, and ricochet risks create hazardous working conditions, while poor visibility limits safe operation, especially in confined or active work areas. Traditional methods cannot safely operate alongside other maintenance or critical, non-stop operations resulting in prolonged and costly downtime, delays and reduced productivity.

-

Traditional blasting methods frequently deliver inconsistent surface preparation, leaving contaminants or damage behind. Over 75% of coating failures are the direct result of poor surface preparation which increases maintenance, rework, and operational costs.

With Matom Sponge-Tech you don’t have to accept these problems anymore.

Used in over 130 countries worldwide, across 14+ industries, Matom Sponge-Tech brings the proven, world leading solution that is Sponge-Jet to British industry, transforming the the UKs approach to surface preparation, surface cleaning and decontamination.

Achieves the highest quality standard for blasting cleanliness (ISO 8501-1:2007)

Suppresses 98% of airborne dust and eliminates harmful rebound.

Sponge abrasive can be recycled and re-used up to 8 times.

95% waste reduction and 90% lower disposal costs.

Can be applied without the need for costly shutdowns.

Highly versatile range of abrasives (0-300µ), for use on all substrates from delicate cleaning to aggressive profiling.

Superior surface preparation extending coating life.

Up to 20 x faster than manual power tools and 3 times more efficient/effective than alternative sponge media.

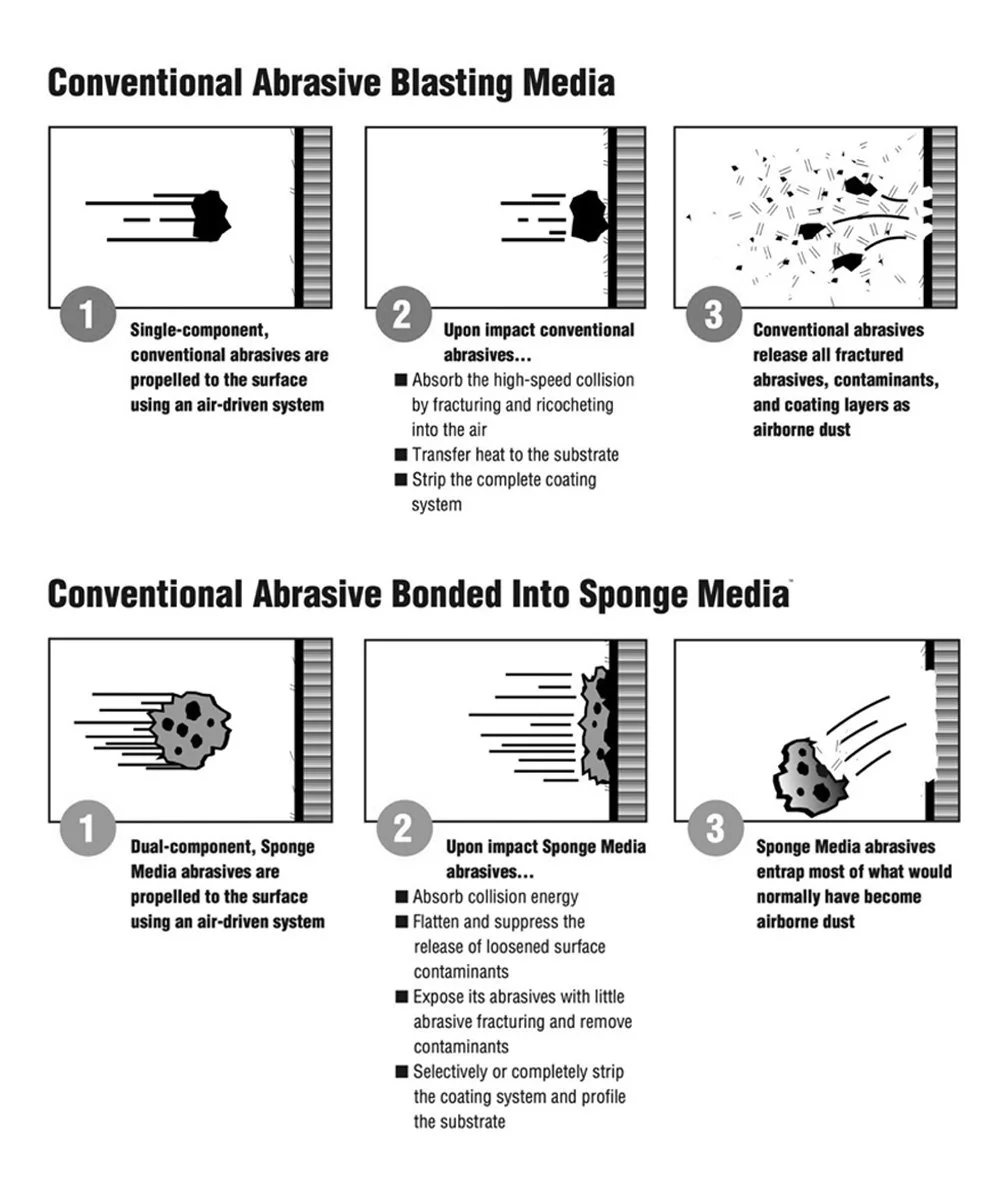

What is Sponge-Jet Technology

Sponge-Jet replaces traditional abrasive techniques with a complete solution that delivers world leading performance, versatility and sustainability. Powered by compressed air and delivered by highly adaptable feed units™ it's patented MicroContainment™ Technology embeds micro-abrasives into engineered synthetic sponge. On impact, the sponge compresses to clean or remove coatings, then expands to capture dust and contaminants before being recycled and re-used. The results are unmatched precision, versatility, effectiveness and safety, whilst dramatically reducing waste and environmental impacts.

Making the switch is simple

Our Proven Process

-

1. Discover

With 25 years of decontamination experience and specialist knowledge of Sponge-Jet, we have proven capabilities that allow us to accurately assess your project goals, challenges and expectations, before identifying how Sponge-Jet can deliver measurable improvements and results.

-

2. Experience

See the benefits of Sponge-Jet firsthand. Through live demonstrations or on-site trials, you’ll witness cleaner, safer, and more precise blasting that reduces waste, downtime, and disruption—proving it's value on your projects.

-

3. Implement

Transition seamlessly with full training, technical support, and integration guidance. Equip your team with the knowledge and confidence to deliver safer, faster and more sustainable results using Sponge-Jet.

98% less airborne dust and debris than traditional blasting, safe for use in confined spaces and robotic capabilities.

Controlled containment and elimination of harmful rebound and re-deposition of contaminants.

Achieves the ‘white metal’ blast cleaning standard (ISO 8501 SA3).

Suitable for all substrates, allows for any desired or required profile (0-300µ).

Adjustable pressure delivery, highly versatile line of abrasive sponge.

Why forward-thinking companies choose Sponge-Jet.

The measurable benefits being felt on a global scale.

From gentle cleaning and aggressive profiling to selective coating removal without damaging underlying substrates.

Industry and sector wide application from restoration to nuclear.

Recyclable and Re-usable, 90% lower disposal costs, environmentally responsible.

Efficient and effective, significantly reduces down time.

Discover the FULL Range of Sponge-Jet Applications

What Our Clients Say

Diverse Industries, Shared Concerns, One Solution

Trusted worldwide, Sponge-Jet has proved itself in the toughest environments and performs for 14+ industries from nuclear to restoration. From surface preparation and surface cleaning to decontamination and abatement, professionals rely on Sponge-Jet for consistent, safe, and efficient results. Whatever the industry, requirement or challenge, the technology always delivers, making it the trusted choice across applications.

-

Nuclear

-

Chemical and Petrochemical

-

Buildings & Infrastructure

-

Contractors and Coating Professionals

-

Facility Maintenance

-

Military

-

Manufacturing

-

Marine

-

Oil and Gas

-

Restoration and Preservation

-

Transportation and Automotive

-

Energy

-

Water and Waste Water

Highly versatile and built to perform.

See how Matoms specialist workforce can help you.

Achieves the ‘white metal’ blast cleaning standard (ISO 8501 SA3)

Capable of delivering precise surface profiles from 0–150+ microns.

ATEX-certified for Zone 2 and Zone 22, for safe and compliant performance in hazardous environments.

SpongeMedia™ meets the blast media standard SSPC‑AB4, ensuring consistent and reliable abrasive performance.

Safe for disposal through incineration.

Ready to explore world leading technology?

Traditional blasting methods create excessive waste, hazardous working conditions, and compliance headaches, often causing costly downtime and inconsistent results. Sponge-Jet’s world leading technology transforms projects by delivering cleaner, safer, and more effective results. Recyclable media reduces waste and supports sustainability goals, while faster cleanup and improved efficiency cut operational costs. Trusted across industries worldwide, Sponge-Jet provides a smarter, environmentally responsible solution that solves long-standing challenges and keeps projects on schedule and on budget.

Contact Matom Sponge-Tech now to find out how Sponge-Jet can transform your project.