advanced dry abrasive blasting technology

get sponge-jet equipment here

what is sponge blasting?

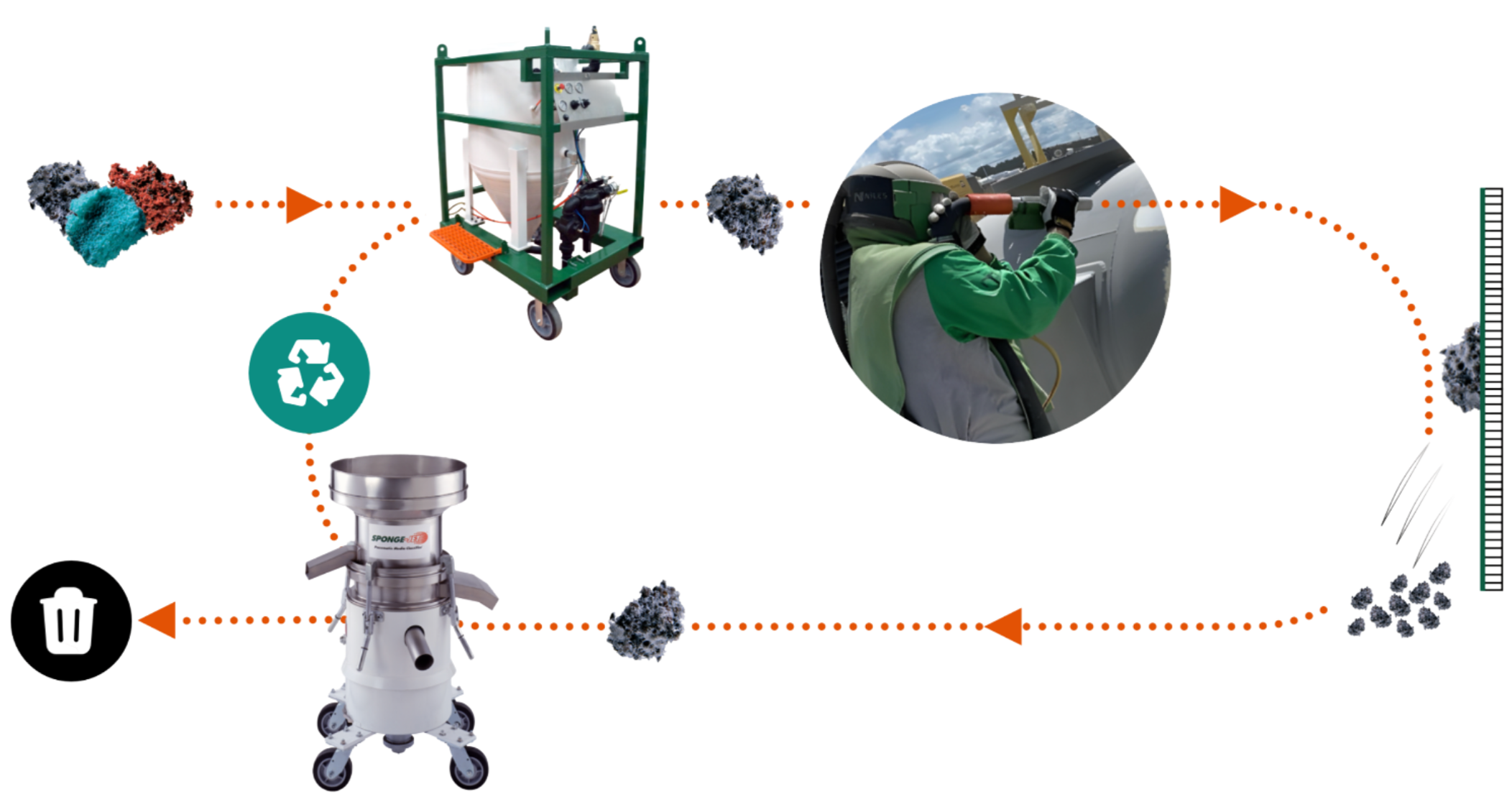

Sponge-Jet Feed Unit™

Sponge-Jet Feed Unit™ propels Sponge Media™ to the surface in compressed air that is controlled through variable blast pressure and media feed rate

Nuclear

facility maintenance

oil and gas

water and waste water

Sponge Media™

A range of Sponge Media™ is available with different micro-abrasive content.

Recycling

Up to 95% of Sponge Media is recycled and reused.

Sponge-Jet Recyclers™

Blasted media is collected and processed, separating reusable media from debris and waste.

Industries using sponge-jet

chemical and petrochemical

Sponge Media™

Sponge Media flattens on impact, exposing abrasive, low rebound, removal and preparation of surface.

Sponge-Jet general overview video

restoration and preservation

buildings & infrastructure

defence

manufacturing

transportation and automotive

contractors and coating professionals

marine

energy

Reduces operational downtime and programme duration - significant cost saving

Suppresses up to 98% hazardous dust reduction

Significantly enhanced visibility during blasting

30× faster than other methods

Extends coating life - reduced maintenance, increased safety, cost saving

Reduces total project cost through faster and more accurate application

Recyclable Sponge Media - up to 12 cycles

Up to 90% lower disposal costs - greater range of disposal options

Eliminates harmful rebound Increased operator and asset safety through reduced Micro-particles and low rebound energy of media

Engineered to minimise fugitive emissions to the environment

key advantages

Better in every way.

Waste reduction - up to 80% volume

Gives desired surface finish including ISO 8501-1 SA 1/2 - 3 (white metal)

Low maintenance plant and equipment

Improved results - achieves desired finish on first application

Widely used in confined space and sensitive environments

Robotic and Bespoke application

Accepted for hazardous waste incineration in the UK (including radioactive materials)

Globally accepted environmental application

Reduced transportation cost

OSHA-recognised

innovative Technology with proven benefits

innovation has to protect people and the planet without compromising on quality, safety and performance

Our Mission & Values

-

Safety First

A safe by design mindset guiding every project.

-

Environmental responsibility

Supporting the reduce, re-cycle, re-use ethos.

-

Operational Excellence

Efficiently delivering quality and excellence.

-

Innovation and Expertise:

Delivering solutions that meet real challenges head on.

What Our Clients Say