Sponge-Jet Technology:

THE Science Behind Superior Results

Engineered abrasives with built-in Micro-Containment™ for controlled, low-dust surface preparation

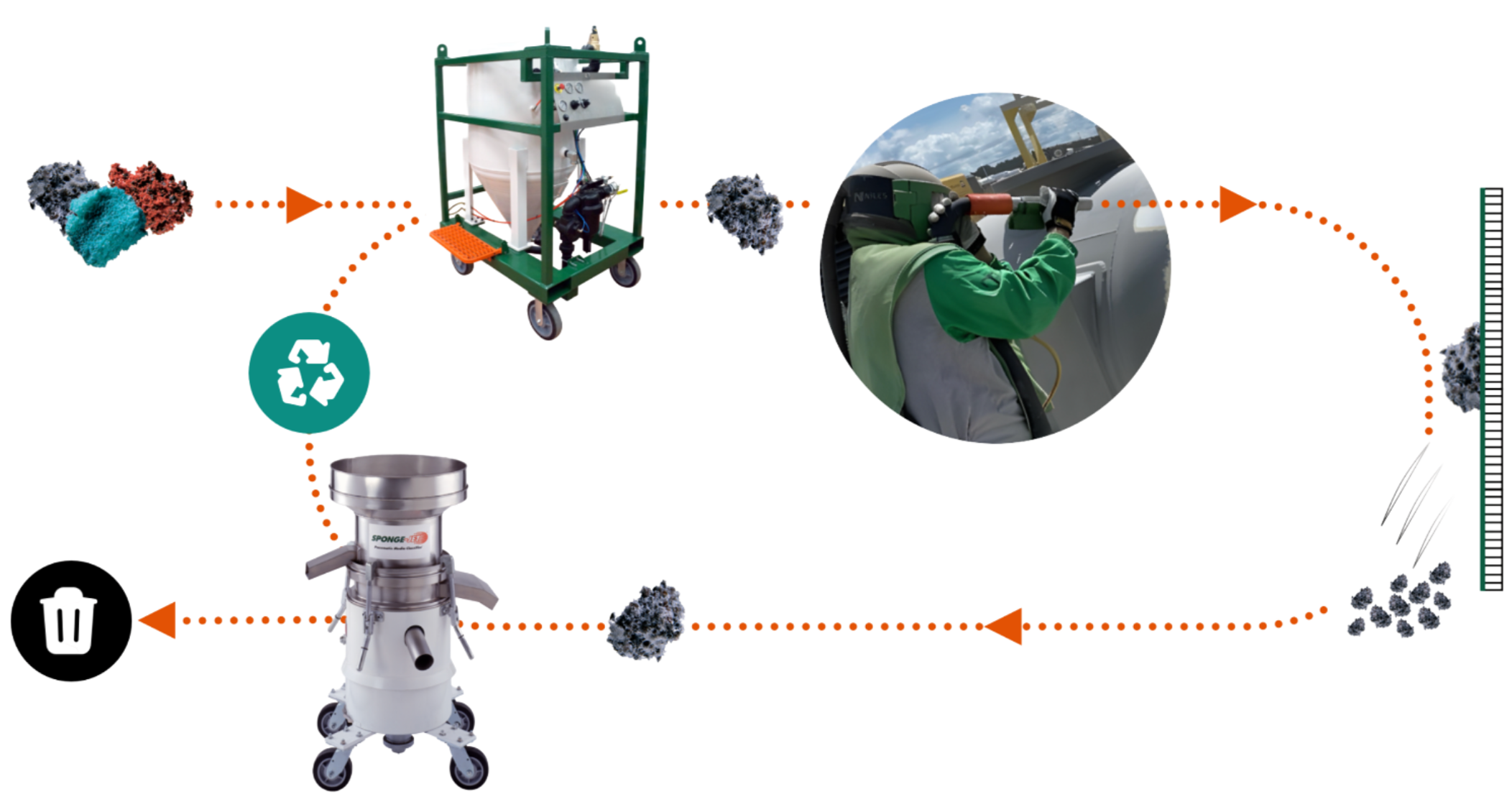

Sponge-Jet technology breakdown:

Sponge-Jet Feed Unit™

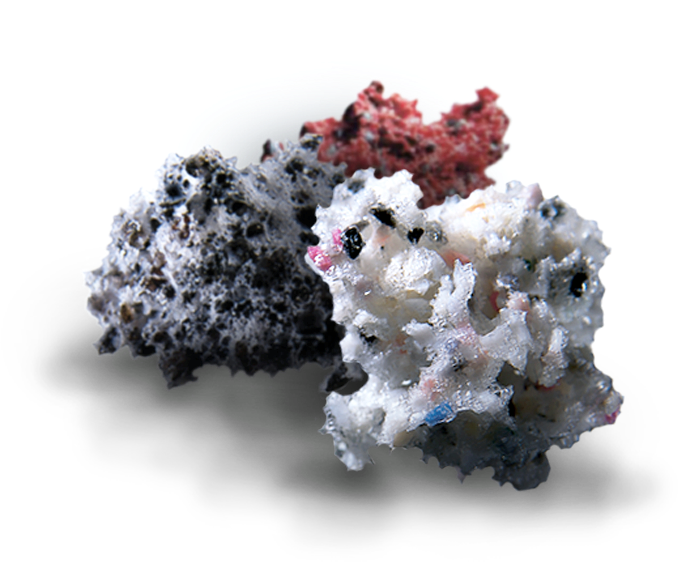

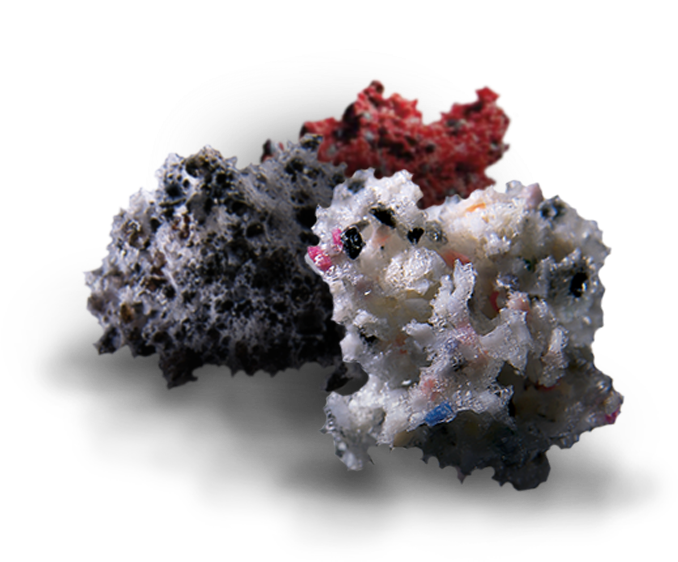

Sponge Media™

Sponge-Jet Recycler™

Sponge Media™

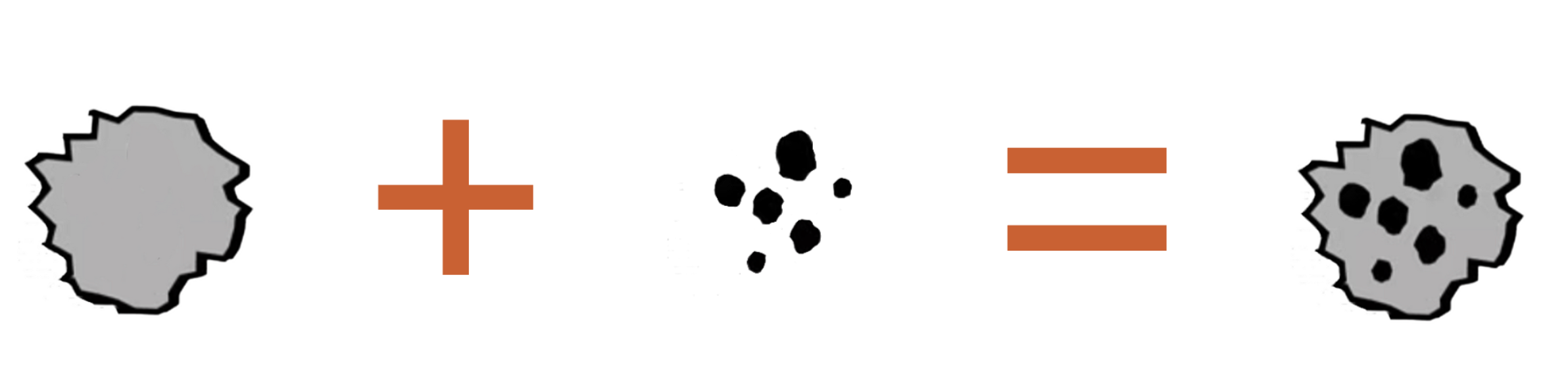

What is it made of?

Abrasive Particles

Polyurethane Foam

How does it work?

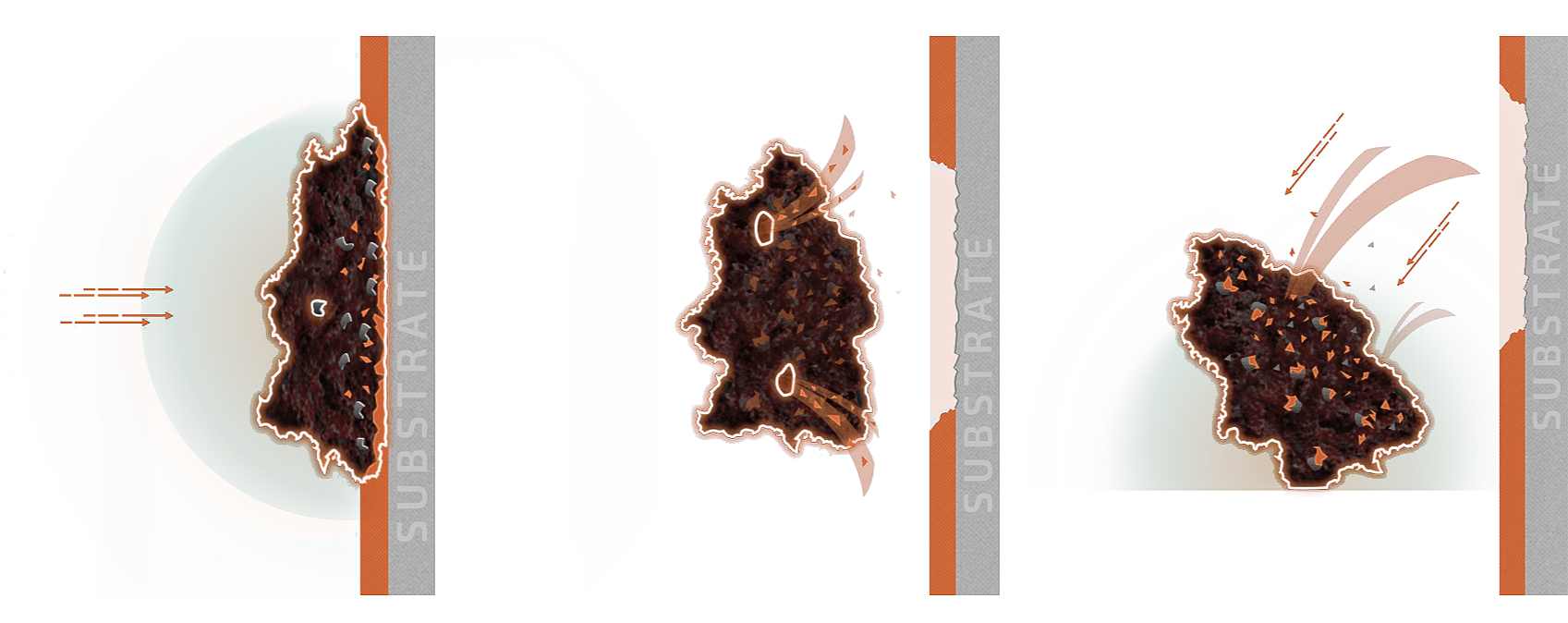

1. Impact - Abrasive Profiling

Media traps hazardous particles (that would have become airborne) and rebounds due to low energy; making cleanup and containment easy.

How does it work?

2. Expansion - Suction

Sponge cells expand, creating vacuum - pulling in debris.

Sponge Media™

3. Containment - Rebound

Sponge Media flattens on impact, exposing abrasive, cleaning, abrading and profiling the surface.

Sponge-Jet Feed Unit™

How does it work?

Propels Sponge Media™ abrasives to the surface using compressed air.

The Sponge-Jet Feed Unit™ uses pneumatic eductors to actively keep the media separated and flowing, ensuring a consistent, blockage-free feed and uniform blasting performance - conventional gravity-fed systems don’t achieve.

A centralised panel provides adjustments of blast pressure and media feed rate to allow precise control and accurate results can be achieved.

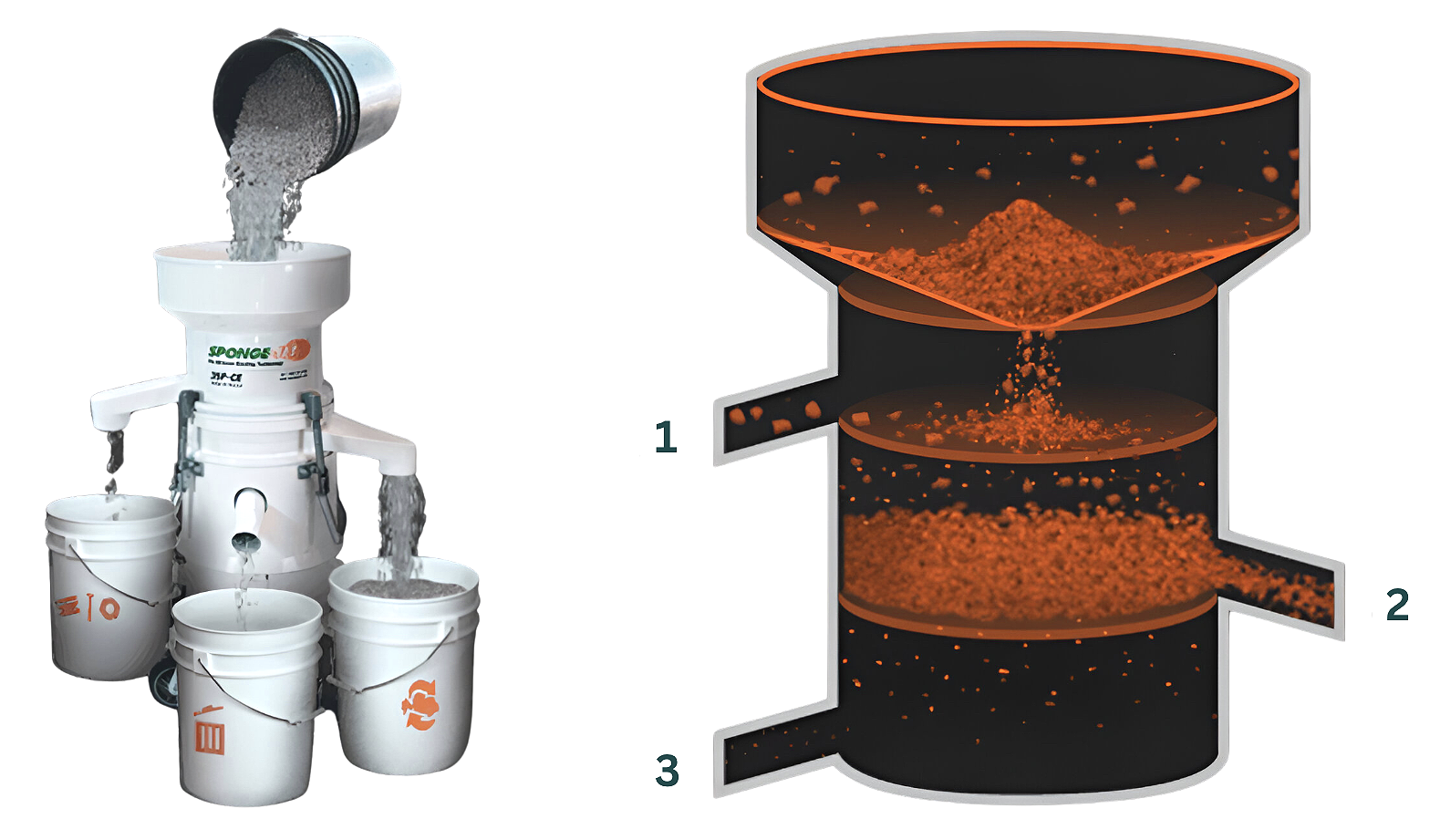

sponge-jet recycler™

3. Fine Waste

Dust, broken down paint, rust and hazardous contaminants are separated from the Sponge Media.

2. Up to 95% recycled

Sponge Media is efficiently recycled on site for immediate reuse, therefore minimising time and cost associated with material handling and waste disposal.

1. Oversized Waste

Removes FOD (Foreign Object Debris).

FAQs

-

Our technical team will advise you on the most appropriate media after reviewing your specific requirements. Trials are available to give assurance for novel requirements.

-

MicroContainment™ captures up to 99% of contaminants at the point of impact, dramatically reducing airborne dust, waste and material recovery compared to traditional blasting.

-

Yes. Sponge-Jet achieves and succeeds surface preparation levels aligned with ISO 8501-1 SA 2 ½ - 3 (White Metal).

-

The Sponge Media absorbs energy and traps spent abrasive and contaminants, preventing them from becoming airborne or spreading across the job site; they are also recyclable.

-

Yes. Reduced dust, rebound, and noise make Sponge-Jet ideal for use in operating facilities, confined spaces, and environmentally sensitive areas.

-

Sponge-Jet works on steel, concrete, aluminium, glass, fibreglassand other substrates. The appropriate Sponge Media™ is selected to meet specific project and surface preparation requirements.

want more information?