why choose sponge-jet?

Superior Results — Saving Time And Money

Up to 99% hazardous dust reduction

Up to 95% waste reduction

Reduce total project cost

Lowers environmental impact

Increase coating life

conventional blasting methods are costing projects

Traditional blasting creates unnecessary and avoidable problems:

Hazardous dust. Excessive waste. Costly and time consuming clean-ups. Lost productivity. Greater environmental risk.

For many industries, that means downtime, disposal headaches and compliance failures that drive costs up and efficiency down.

None of it is necessary.

There is a better way with Sponge-Jet, see why…

Conventional Abrasive Blasting

Sponge-Jet Blasting

Shared Goals, Shared Challenges, the solution? Sponge-Jet.

Designed to perform where others fail.

For surface preparation that’s proven and trusted around the world, nothing matches the versatility, safety and consistency of Sponge-Jet.

When performance matters, the results speak for themselves.

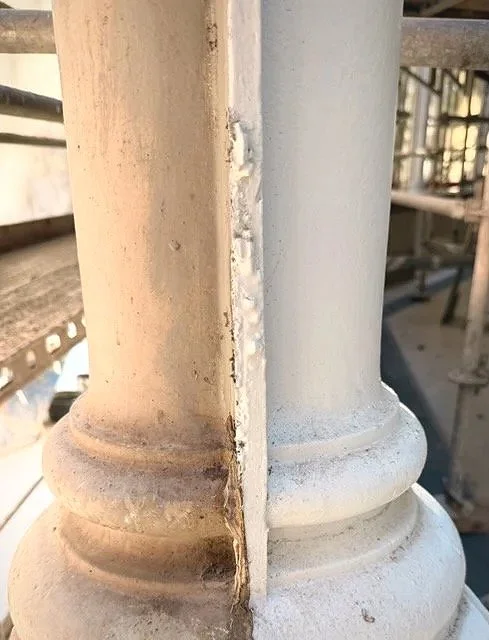

Before & After surface preparation and painting

99% less airborne dust and debris vs conventional blasting methods.

Used in confined spaces and robotic capabilities.

Controlled containment and elimination of harmful rebound and re-deposition of contaminants.

Achieves and exceeds ISO 8501-1 SA3 cleanliness grade

Suitable for all substrates, allows for any desired or required profile (0-300µ).

Bespoke technology

Why innovative companies choose Sponge-Jet.

The measurable benefits being felt on a global scale.

Total surface control, from gentle cleaning to aggressive profiling, without substrate damage.

Industry and sector wide application from restoration to nuclear.

Recyclable and Re-usable (up to 12 times)

90% lower disposal costs, environmentally responsible.

Significantly reduces down time.

Discover the FULL Range of Sponge-Jet Applications

GET IN TOUCH

Matom SpongeTech

Unit 44B, Ffordd William Morgan,

St Asaph Business Park, St Asaph, Wales. U.K. LL17 0JG

Tel: 01745 421019

Email: spongetech@matom.com